Project Brief

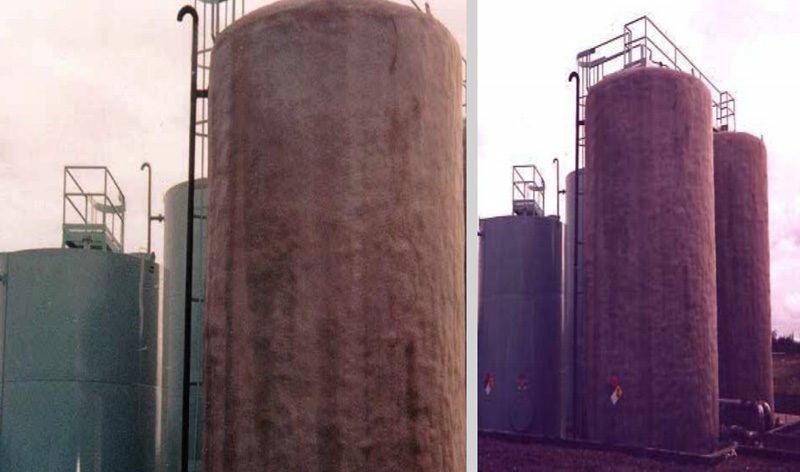

PROJECT: Great Western Chemical Tank Farm

LOCATION: Fairbanks, AK

OWNER: Ghemm Company

APPLICATION: Klondike Foam & Coating

COATING SYSTEM: Tanks coated with 150mm of 1Kg density. Polyurethane foam with

1mm of PolyShield HT™ 100 Polyurea High Pigment/UV Aluminum

TOTAL AREA: Two tanks at 113,000 Litres each. Concrete Liner 111m₂

COMPLETION DATE: Storage Tanks – Oct. 1994 / Concrete Liner – June 1995

PROBLEM

Great Western Chemical needed a complete performance coating for their two storage tanks. A protective lining was needed for the exterior, with a secondary protective coating to stop potential leaks from damaging ground soil. The tanks also needed a new layer of insulation, as the previous coating had been damaged by nesting birds.

Our Solution

SOLUTION

A PolyShield HT™ 100 polyurea coating was selected for its fast-set, abrasion resistant (i.e. bird-proof) qualities. The owner appreciated the performance coating’s superior adhesion and ability to quickly form a seamless membrane. The two 113,000 litre tanks were cleaned, then sprayed with 150mm of 1 kg density polyurethane foam. A layer of PolyShield HT™ 100 High Pigment-UV polyurea coating was applied at 1mm to the foam surface. In addition to the tanks, the concrete dikes were sprayed with a black PolyShield HT™ 100 performance coating at 1 mm to provide a reliable secondary protective lining.

RESULTS

18 months after the initial application, the polyurea coating was found to be performing well, with some minor discoloration. The owner was pleased with the outcome, and confident that the performance coatings provided a solution to their problems. Today, 22 years on, the protective linings remain as solid as ever, with 3 more years left on SPI’s guarantee.